Plasma sterilizers

Low Temperature Plasma Sterilization: An Innovative Approach for Effective Pathogen Elimination

Introduction:

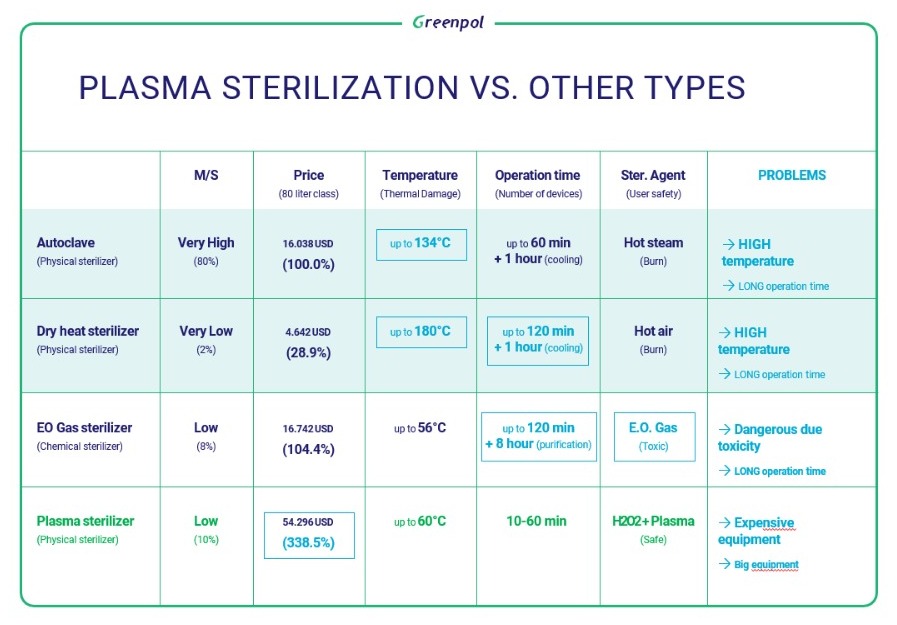

Sterilization is a critical process employed in various industries, including healthcare, pharmaceuticals, and food manufacturing, to eliminate or deactivate microorganisms and ensure the safety of products and environments. Traditional sterilization methods often involve high temperatures, chemicals, or radiation, which may not be suitable for certain sensitive materials or equipment. However, low temperature plasma sterilization has emerged as an innovative and effective alternative, offering a safe and reliable means of achieving sterilization without compromising the integrity of the treated items. In this article, we explore the principles, applications, and advantages of low temperature plasma sterilization.

Understanding Low Temperature Plasma Sterilization:

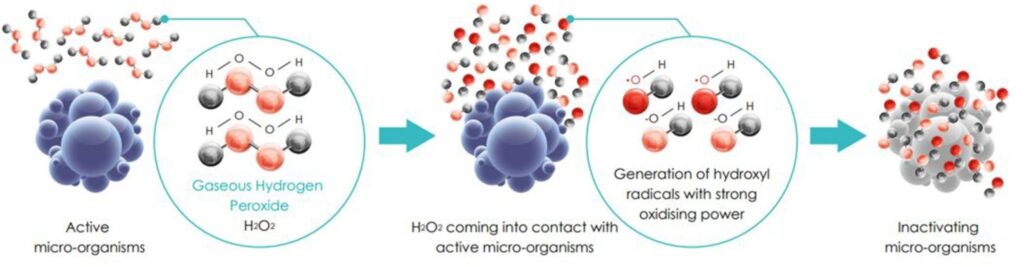

Low temperature plasma sterilization is a non-thermal sterilization technique that utilizes ionized gases to create a unique plasma state at low temperatures. Plasma, often referred to as the fourth state of matter, consists of neutral and charged particles that are electrically conductive. The plasma state can be generated using different gases, such as hydrogen peroxide (H2O2), oxygen (O2), or a mixture of gases, in combination with an electrical discharge.

How Low Temperature Plasma Sterilization Works:

The process of low temperature plasma sterilization involves several key steps:

- Chamber Preparation: The items to be sterilized are placed within a sealed chamber. The chamber is then filled with the selected gas or gas mixture.

- Plasma Generation: An electrical discharge is applied to the gas, creating plasma. This discharge can be achieved through various methods, including radiofrequency or microwave energy.

- Sterilization Cycle: The plasma interacts with the gas molecules, generating reactive species such as free radicals, ions, and UV radiation. These highly reactive species effectively destroy microorganisms by damaging their cellular structures and genetic material.

- Aeration: After the sterilization cycle, the chamber is aerated to remove any residual gas or by-products, ensuring the safety of the sterilized items.

Applications of Low Temperature Plasma Sterilization:

Low temperature plasma sterilization offers numerous applications across different industries:

- Healthcare: In hospitals and healthcare facilities, low temperature plasma sterilization is used for the sterilization of heat-sensitive medical devices, surgical instruments, and implants. It provides a gentle and efficient sterilization method for delicate instruments that cannot withstand high temperatures.

- Pharmaceuticals: Low temperature plasma sterilization plays a crucial role in pharmaceutical manufacturing, ensuring the sterility of drugs, vials, and packaging materials. It eliminates the risk of contamination without altering the chemical properties of the pharmaceutical products.

- Food Industry: Plasma sterilization finds utility in the food industry for the decontamination of packaging materials, food processing equipment, and surfaces. It helps extend the shelf life of food products and ensures their safety by eliminating pathogens and spoilage organisms.

Advantages of Low Temperature Plasma Sterilization:

- Compatibility: Low temperature plasma sterilization is compatible with a wide range of materials, including metals, plastics, rubber, glass, and fabrics, making it suitable for diverse applications.

- Environmentally Friendly: The process does not require the use of harmful chemicals or high temperatures, minimizing environmental impact and reducing the risk of chemical residue on treated items.

- Short Cycle Time: Compared to other sterilization methods, low temperature plasma sterilization offers faster cycle times, allowing for increased productivity and reduced downtime.

- Safety: The process is safe for operators and patients since it does not produce toxic by-products or harmful radiation. It is also non-corrosive to equipment and does not cause discoloration or degradation of materials.

Low temperature plasma sterilization has emerged as an innovative and effective method for achieving pathogen elimination and ensuring the sterility of various products and environments. Its compatibility with a wide range of materials, minimal environmental impact, short cycle times, and overall safety make it a valuable alternative to traditional sterilization methods. As technology advances, low temperature plasma sterilization is likely to become even more widely adopted, contributing to enhanced safety standards across industries and ultimately improving public health and well-being.

How does a plasma sterilizer work?

The plasma sterilizer uses hydrogen peroxide vapor to destroy microorganisms without any toxic by-products. As a result of the sterilization process, only water vapor and oxygen are produced. Plasma supports sterilization and the decomposition of hydrogen peroxide remaining after the end of the sterilization process. The maximum sterilization temperature is below 59 ° C.

This technology is suitable for the sterilization of a wide range of medical instruments and devices, especially those that are sensitive to the effects of higher temperatures and humidity. It guarantees the immediate use of sterilized equipment. Only electric power is required for installation (no other utilities required). Unlike gas sterilization, no external ventilation system is required.

Plasma in HMTS sterilizers is generated outside the arc chamber and not in the chamber by radio frequency waves as in many plasma sterilizers on the market. The advantage of creating plasma outside the chamber is that the process is not disrupted by touching the packet to the wall of the chamber, it is not sensitive to moisture, and the chamber has a larger usable area.

Advantages of plasma sterilization:

- It leaves no harmful residues and is environmentally friendly. As a result of the plasma sterilization process, only water vapor and oxygen are produced.

- Short sterilization times: Surface (29 min / 21.5 min) / Standard (39 min / 38.5 min) / Container (49 min / 49.6 min)

- Only electricity is required for sterilization.

- Unlike gas sterilization, no external ventilation system is required.

- The maximum working temperature is below 59 ° C.

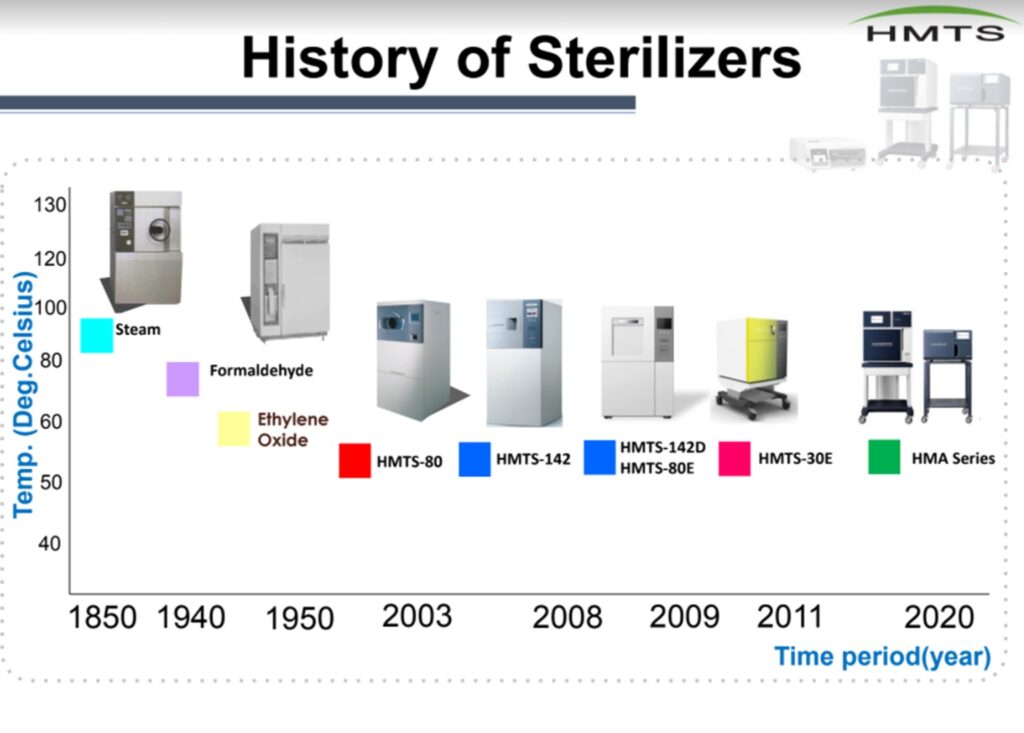

History of plasma sterilizers

Humanmeditek plasma sterilizers were introduced to the market in 2003. They are manufactured in South Korea, which is one of the largest manufacturers of plasma (low temperature) sterilizers in the world. Humanmeditek was the first Korean company to produce a plasma sterilizer.

Materials that can be sterilized in the plasma sterilizer:

Metals

- 300 series stainless steel

- 6000 series aluminum

- Titanium

Materials other than metal

- Acrylonitrile butadiene styrene (ABS)

Polycarbonate - Delrin

Polyetherimide - EVA (Vinyl Ethyl Acetate)

Polyethylene Terephthalate (PET) - Fluorinated ethylene propylene (PFTE)

Methyl polyacrylate (PMMA) - Glass, USP type 1 borosilicate

- Polyphenylsulfone

- High-density polyethylene

- Polypropylene

- Kraton Polystyrene

- Polysulfone latex

- Low-density polyethylene

- Polytetrafluoroethylene

- Monel Polyurethane

- Neoprene rubber (polychloroprene)

- Polyvinyl chloride (PVC)

- Nylon Silicone

- Phenolic resin

Materials that cannot be sterilized in plasma sterilizers:

- Absorbent materials (cellulose), wood, canvas, paper, sponge, disposable suture materials

- Liquids (wet materials)

- Powders

- Oils

Technologies used in Explasma plasma sterilizers:

P-ART - ARTIFICIAL RESPIRATION TECHNOLOGY

P-ART technology is the unique technology of the CUBE Instrument. This may result in repeated penetration of the sterilant into the medical device, e.g. artificial suction shortens the sterilization time. It is very effective at changing temperature and removing moisture.

SAE-I (Sterilization Acceleration Engine) - "Space Variable Technology" chamber - technology that optimizes sterilization and heat transfer by changing the pressure inside the chamber. (Patent application August 2016, registration 2017.04 (KR) (1st Generation Technology)

AMR - AUTOMATIC HUMIDITY REMOVAL

EXPlasma has an automatic dehumidification function. Thus, it can be conveniently and safely used, even if it has little humidity or a slight temperature difference.

CONDENSATION PHENOMENON

Low temperature plasma sterilizers are sensitive to humidity and temperature differences.

If there is moisture or temperature difference, the hydrogen peroxide used as a sterilant may be on the medical device. Heating and dehumidification are very important. EXPlasma is a sterilization solution that can minimize these problems.

Plasma sterilization can be used in:

- Dental clinics

- Ophthalmological clinics

- Urology clinics

- Hospitals

- Veterinary clinics

- Plastic surgery clinics

- Tattoo studies

- Everywhere where treatments interfering with human solid tissue are carried out

Biological tests for low-temperature sterilization

- Biological tests according to Humanmeditek recommendations should be performed at least once a day, unless the hospital has its own procedure (PSSM Recommendation - biological tests for each load)

- The sterilized load should be released after receiving a negative result (no microbial growth).

Benefits of plasma sterilisation, (H2O2) low-temperature sterilisation are:

Plasma hydrogen peroxide (H2O2) sterilization, also known as vaporized hydrogen peroxide (VHP) sterilization, is a technique used to sterilize medical equipment, devices, and surfaces using a combination of plasma and hydrogen peroxide. The benefits of using plasma H2O2 sterilization include:

- Effective sterilization: Plasma H2O2 sterilization is an effective way to kill microorganisms on surfaces and equipment. It can eliminate bacteria, viruses, and fungi, including drug-resistant strains.

- Safe and non-toxic: Plasma H2O2 sterilization does not use toxic chemicals, making it a safe and non-toxic method of sterilization. It does not leave any harmful residues on surfaces or equipment, reducing the risk of contamination.

- Environmentally friendly: Plasma H2O2 sterilization is an environmentally friendly method of sterilization since it uses hydrogen peroxide, which breaks down into water and oxygen. It does not produce any harmful byproducts or residues, reducing the risk of environmental contamination.

- Short cycle time: Plasma H2O2 sterilization has a short cycle time, which means it can sterilize equipment and surfaces quickly. This can increase efficiency in healthcare settings, allowing medical professionals to treat patients faster.

- Compatibility with sensitive equipment: Plasma H2O2 sterilization is compatible with a wide range of equipment, including sensitive materials such as plastics and electronics. It does not damage or degrade these materials, making it a versatile sterilization method.

- Penetration: Plasma H2O2 sterilization can penetrate small spaces and hard-to-reach areas, ensuring complete sterilization of all surfaces and equipment.

- Safety: Plasma H2O2 sterilization can be performed safely in occupied rooms, which means that medical professionals can continue to work in the same area during the sterilization process.

Overall, plasma H2O2 sterilization is a safe, effective, and environmentally friendly way to sterilize medical equipment and surfaces. It can help reduce the risk of healthcare-associated infections and increase efficiency in healthcare settings.

Why low temperature plasma steriliser is better than autoclave?

Low-temperature plasma sterilizers use a combination of hydrogen peroxide vapor and plasma energy to kill microorganisms on medical equipment. This method has several advantages over autoclaves, including:

- Compatibility with heat-sensitive materials: Low-temperature plasma sterilizers can sterilize heat-sensitive materials, such as plastics and electronics, without damaging them. Autoclaves, on the other hand, use high temperatures and pressure that can damage or melt these materials.

- Shorter cycle time: Low-temperature plasma sterilizers can sterilize equipment in a shorter time than autoclaves. This means that medical facilities can turn over equipment more quickly and efficiently.

- Less water usage: Autoclaves use water to create steam for sterilization, which can be a scarce resource in some areas. Low-temperature plasma sterilizers do not require water.

- No need for ventilation: Autoclaves require a ventilation system to remove the steam and prevent it from damaging the equipment or environment. Low-temperature plasma sterilizers do not require ventilation.

- Easier to maintain: Low-temperature plasma sterilizers require less maintenance than autoclaves because they do not have moving parts that can wear out or break.

Overall, low-temperature plasma sterilizers offer several advantages over autoclaves, particularly in terms of compatibility with heat-sensitive materials and shorter cycle times. However, they can be more expensive than autoclaves and may require additional training and expertise to use effectively.